The LAB2104 is situated at Technical University in Plovdiv – Bulgaria. Bulgaria is a small country in the European Union and Plovdiv will be the European Capital of the Culture in 2019. The laboratory specialize analog magnetic recording in parallel with the research on the embedded systems and electronics. About the magnetic recording It is very important to use good test equipment and test tools to ensure good final results. First of all the oscilloscopes are good tools for tuning the bias oscillators and bias traps. We have good digital oscilloscopes to do that in the lab. The other important things are the reference test tapes. After the repair procedure of the tape deck it must be tuned to the standard values for tape speed, azimuth, frequency response, tape tension and etc. This is done using reference tapes for speed, level and azimuth. Bo th tapes are expensive and rare tools. We have enough reference tapes to tune precise every cassette and tape deck. The azimuth tuning is done using X/Y phase method. This process uses reference 10kHz test cassette. First the process is done on peak amplitude. The fine tune is done to get a 45 degree line on the X/Y chart and that ensures the minimal

th tapes are expensive and rare tools. We have enough reference tapes to tune precise every cassette and tape deck. The azimuth tuning is done using X/Y phase method. This process uses reference 10kHz test cassette. First the process is done on peak amplitude. The fine tune is done to get a 45 degree line on the X/Y chart and that ensures the minimal  phase shift between the channels of the full track test tape. For the reference level we use IEC tapes for the Philips 0dB VU level (160nWb/m), also the Dolby level tape (200nWb/m ANSI) and the IEC 0dB referred to 250nWb/m.

phase shift between the channels of the full track test tape. For the reference level we use IEC tapes for the Philips 0dB VU level (160nWb/m), also the Dolby level tape (200nWb/m ANSI) and the IEC 0dB referred to 250nWb/m.  Other important thing is to check the Wow & Flutter of the machine. We used reference test tapes with W&F < 0.015% WRMS. We have equipment to measure different standards for the W&F including DIN, NAB, CCIR and JIS. The values can be read on peak, mean or rms (WTD). The frequency response is checked using precise spectrum analyse. It shows the amplitude of mix tones.

Other important thing is to check the Wow & Flutter of the machine. We used reference test tapes with W&F < 0.015% WRMS. We have equipment to measure different standards for the W&F including DIN, NAB, CCIR and JIS. The values can be read on peak, mean or rms (WTD). The frequency response is checked using precise spectrum analyse. It shows the amplitude of mix tones.

You can see some photos of the laboratory equipment and the reference test tapes and cassettes that we use.

Software tools for phase measurement (azimuth setting) and frequency response tests. Also some of the oscilloscopes (Rohde & Schwarz, UNI-T).

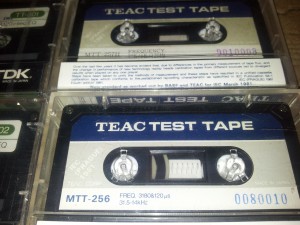

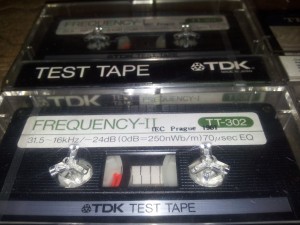

Test cassettes for azimuth, speed, frequency analysis, Dolby, DIN and IEC reference level, Wow and Flutter, etc.

We have a lot of test tapes for azimuth alignment (and PB frequency response). All the azimuth tapes have full compatibility each other. The azimuth test tape that we use is the Sony P-4-A100. The frequency response test tapes (which can be used also for azimuth adjustment) are MTT-256 (31Hz to 12.5kHz sets) and MTT-257H (10kHz/1kHz/125Hz):

A list of speed alignment test tapes. Both can be used for precise WOW&FLUTTER analysis. One of the tape is for the DIN measurements (3.15kHz), the other is for JIS (3kHz). The tapes are precise and have own w&f < 0.015% (JIS WRMS). The 3kHz test tape is the Sony WS-48A, while the DIN 3.15kHz test tape is the ABEX TCC-113 (3.15kHz recordet at 160nWb/m):

Reference level tapes are very important for the correct work of Dolby systems and all other noise reduction systems. There are different reference level standards. We have tapes for the DIN 0dB=160nWb/m, the new IEC based on 0dB=250nWb/m, also the reference of the Dolby level (which 200nWb/m ANSI or 218nWb/m DIN). The DIN reference test tape is MTT-256, while the IEC are MTT-212N (315Hz) and MTT-112BN (1kHz):

The most urgent test tapes are the Dolby reference test tapes. The flux of these test tapes corresponds to the reverence voltage level of the Dolby chips. That ensures compatibility of the Dolby system between different chips and machines. We use ABEX TCC-130 and TEAC MTT-150 test tapes (200nWb/m ANSI which corresponds to 218nWb/m DIN). Nakamichi reference test tape uses 200nW/m by DIN, so it is not exactly Dolby test tape. That is why their machines are tuned for less voltage on the reference Dolby test points.

The torque test tapes are very important for the correct tape drive functionality. It is very important on machines equipped with dual capstans. One of the tape measures the tension on fast rewind and forward, the other measures the back tension (which must be in the range of 7 to 9 gr/cm for the dual capstan machines) and the take up tension. The tension tapes we used are the TMK TC-012 and K-Media KM-F, all made in Japan:

The head calibration gauge (M-300) is important for the setting up the correct head position (height, tilt, zenith):

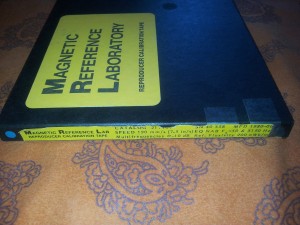

Some of the test tapes: Matsushita (for the NAB on 7.5 ips), Kudelski/Nagra (for the NAB 9.5cms/s, IEC 7.5 ips, IEC 15 ips), MRL (for the NAB on 7.5 ips):

Precise voltage true RMS meters. The meters can measure the true RMS voltages of about 0.1mV. That is dynamic range of about -80dB and more, which is good enough for most of tape machines.

Precise W&F meters (Kenwood & Leader, made in JAPAN) for the IEC, DIN, NAB and JIS. Readings are in the range 0.001% up tp 3%.

New full track test tape for the NAB on 7.5 ips based on the R2R Technics RS-1500 models.

“Tentelometer” – a tool for measurement the tape tension

Some MRL test tapes for 19 cm/s and 38cm/s for the NAB and IEC strandards

Pingback: Cost for Tape Decks repair @LAB2104 | LAB2104